The usable capacity is around that of 5 x 100ah lead acid batteries. This is roughly the size of an 80ah lead acid. The weight is 22.5kg and the dimensions of the pack (excluding the case) are 290 mm width, 175 depth, and 200 mm height. The battery management system is the 123SmartBMS and combined with the 123Smart pair of bistable relays.

Diy lifepo4 battery box series#

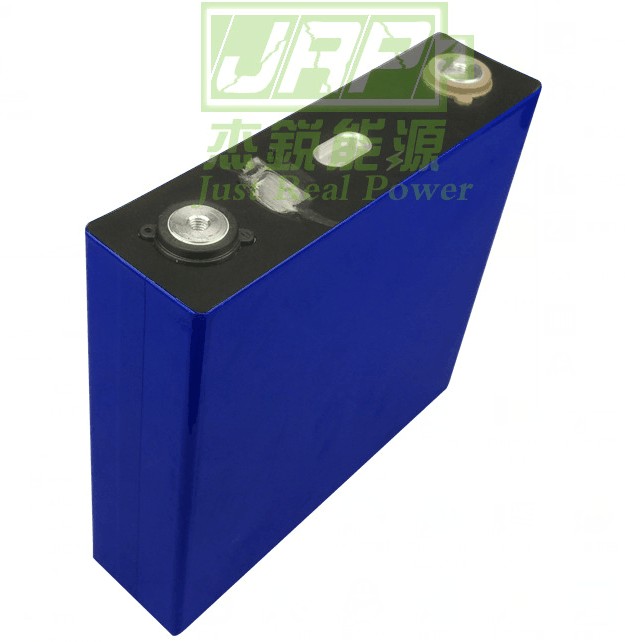

The four cells are aluminium cased, 3.2 volt and 271 ah arranged in series (4S configuration) to form a nominal 12 volt battery. All charging sources and regulators that will ever feed the new battery need to be re-assessed for suitability: either they can be reconfigured to operate acceptably, or they will need replaced.Electronic protection circuitry must be installed to ensure that none of the cells can ever exceed their operating voltage limits and the battery never starts heating up.The cells that will make up the battery need to be charged and carefully balanced before they can be interconnected to form a bank.High-current DC disconnectors must be installed in the paths between the battery and the new busbars, so the battery can be isolated from loads and/or charging sources if needed.At a minimum, the positive bus must be split into distinct charge and load buses and the corresponding cabling moved. On a standard, tidy installation, it all leads to positive and negative busbars. Before even considering sourcing any battery cells, the onboard electrical system must be reviewed and all connections pertaining to loads must be physically separated from charging sources.I may discuss his point 5 later but it is enough to say upfront that the design has to be for a lithium system which includes all charging, not simply for a lithium battery. Note that no so called LFP ‘drop-in battery’ can meet this first principle since loads and charging cannot be separated. I am not planning to use an inverter so this will be plenty for my usage. You will see from the photo that the load and charge circuits are separated and can be interrupted by bi-stable relays rated up to 120amps. The pack itself (as seen in the photo) conforms to the first four of Nordkyn’s main principles of design (below). I know it will work – most things work to begin with - what I don’t yet know is whether it will endure over a long period of years in a marine environment. The other significant warning I have to give is that my pack, while completed, balanced and tested has yet to be fitted to the boat – it should be by the autumn.

Diy lifepo4 battery box how to#

LiFePO4 Batteries On Boats - Marine How To You are unlikely to burn down your boat (or no more likely than with lead acid) but you may burn a big hole in your wallet.įor anyone still new to LFP I recommend the series of six articles by Nordkyn Design and the long article by Rod Collins of Marine How To.

Diy lifepo4 battery box full#

Even a modest DIY build such as this represents a substantial financial investment for most which will prove cost-effective only if it is allowed to live a full life of 10-15 years. It is important to understand how very different LFP is from lead acid to avoid costly errors. I hope the thread will stimulate people to think about the issues and the choices, rather than slavishly copy. For those with other agendas there are alternative threads where you can declare how ruinously expensive you think LFP is, how readily it will burn a boat down, and how, having given it your full consideration, you would never touch it with a bargepole. I’d prefer, in this discussion, just to concentrate on the choices made. In another thread I had some small encouragement to document my LFP (LiFePO4) build.

0 kommentar(er)

0 kommentar(er)